PAGE CONTENTS:

VERMONT PHOSPHORUS INNOVATION CHALLENGE SPRING 2022 UPDATE

Four VPIC Participants are engaged in Stage Three agreements, awarded in November of 2019.

DVO, Inc./ University of Vermont (UVM)

During Stage Three, DVO has engaged in two different studies to explore methods of drying materials produced from anaerobic digesters at dairy farms, to then be enhanced using a Dissolved Air Floatation Device (DAF) process capturing valuable nutrients for advanced solids control. The goal of the project is to develop a ‘P-Cake’ product that is high in phosphorus and other nutrients. This material can then be processed, bagged and/or bottled as a marketable retail product, in addition to being used to create, sell, and distribute bulk fertilizer and soil amendment materials from a facility established in Vermont.

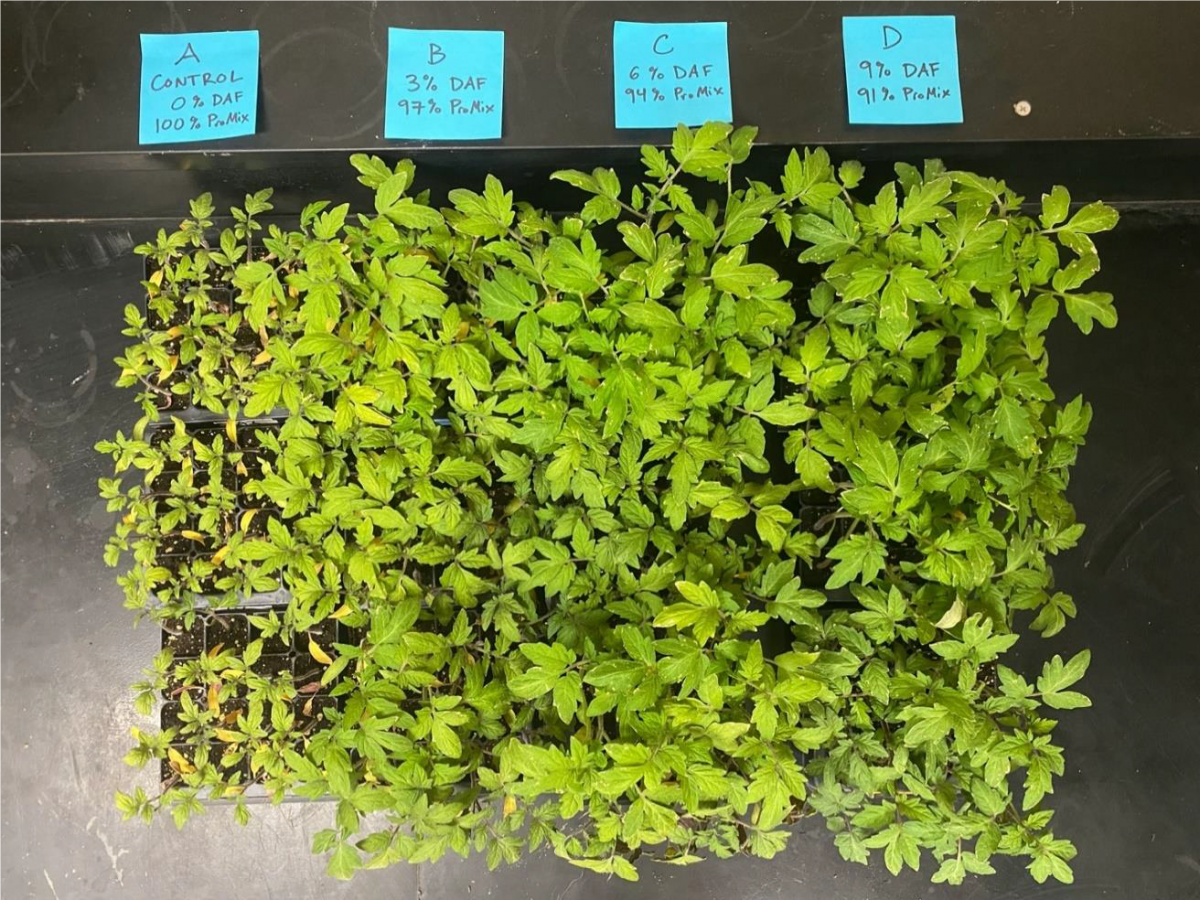

The remaining hurdle for DVO in full execution of their proposal is perfecting a drying method for the materials produced from the DAF solids. DVO had initially proposed the use of quicklime (QL) as an additive to decrease moisture in the products without impacting growth or germination rates. Unfortunately, this method – while adequately drying the material, did impact growth yields due to changes in pH, as well as biding up nutrients and making them unavailable to plants. The second drying method, the use of a centrifuge to dewater the DAF solids to a level that is manageable without incurring substantial nutrient losses from the solids, concluded in December of 2020. The method was not deemed a viable option for drying the DAF material as the moisture content attained through the Centrifuge process was too high, resulting in a product that had unimpacted growth impacts, but was still too wet to manage and process into a bagged product.

DVO explored the use of a ring dryer to decrease the moisture content of the materials such that it could be managed and processed. However, the logistics and operating costs of this equipment proved to be exceedingly expensive, making this option infeasible. In an effort to overcome the obstacle of drying the DAF material, the University of Vermont, who had been a partner to DVO throughout the course of this VPIC project, accepted a subsequent grant in August 2021 to further explore thermal drying of the DAF material in the hopes of creating a product that has an acceptable composition, is friable, and is considered a saleable product.

This research trial was completed in December of 2021 with the submission of a Final Report detailed additional bench top trials testing the impacts of thermal drying of the material on Nitrogen content and friability through ryegrass and tomato seedling bioassays. The results indicated continued difficulty with dewatering of DAF materials without impacting nutrient yields and friability of the products, thus continued research is necessary to solve this complex and critical question. Once this barrier has been solved, it will be nothing short of a monumental achievement, and several external organizations have indicated interest pursuing this work. At this point in time, the VPIC Leadership team has determined that the submittal of this Final Report concludes this VPIC Project, with the hopes that this research can continue through other means to eventually solve his hurdle.

Results for tomato seedling bioassay illustrating the fertilization effect of DAF solids. (UVM Photo)

Digested Organics

Digested Organics has been engaged in the fabrication and construction of a mobile manure screening and ultrafiltration system to be used on a Vermont dairy farm to remove >95% of the phosphorus, >99% of the suspended solids, and >99.9% of pathogens in liquid manure, the UF System. The remaining liquid is ideal for field application (80% of the initial manure volume) and the concentrated fertilizer is readily transportable (20% of the initial manure volume). By concentrating phosphorus, this technology allows the farm to apply phosphorus more economically on lands that are further away and typically lower in soil phosphorus, as well as transport the material to nearby compost facilities for stabilization and incorporation into value-added products.

The design for the UF System is complete, as is the fabrication of the UF module. This system can process about 3,000 GPD of manure (about 100 cows) and generate around 2,000 GPD of permeate. The permeate will flow by gravity to a nearby storage lagoon and the concentrate will be collected in a tank at the site, where it will then be transferred to the composting operation run by Agrilab Technologies (another VPIC Participant).

Throughout this VPIC Project, the largest unknown factor was addressing electrical service needs, specifically 3-phase power. 3-phase power is needed first of all for the Digested Organics’ UF units, and can be exceedingly expensive to establish. Following exploration of options for 3-phase at several Magnan Brothers farmstead so the UF unit would be co-located with the CAHR unit, it was determined that this location was not viable, as the estimates for establishing 3-phase power were cost prohibitive. Following this conclusion, Digested Organics connected with Chris Wagner of Green Dream Farm, located in Enosburg Falls, VT. Green Dream has existing 3-phase power and a Cri-man Screw Press to initially process material before going through the UF unit. The screw press is undergoing repairs and is predicted to be fully operational in the near future. As the UF concentrate will now be located off-site from the CAHR unit; it will be transported in 330-gallon totes via hired tanker trucks using pickup trucks or trailers.

The UF system, in the portable trailer, was delivered to Vermont on September 30, 2021, later than expected due to further delays caused by Covid-19. Several Digested Organics personnel and affiliated team members were onsite to assist with installation and commissioning. All systems were found to be fully functional. The concentration storage tank was delivered and erected, in additional to heat traced and insulated storage hoses. The UF unit, including the portable trailer, was prepared for cold weather operations with additional insulation. Once the screw press has been fully repaired, the UF unit will be able to start filtering material. Updates in January of 2022 indicated some obstacles associated with the UF unit’s filtering capabilities due to cold weather, which will be further documented in subsequent updates.

Mobile Ultrafiltration System ready for transport. (Digested Organics’ Photo)

Agrilab Technologies Inc.

Agrilab Technologies Inc.’s (AGT) Stage Three VPIC proposal includes the establishment of a hub and spoke network of five on-farm composting and phosphorus processing sites. AGT has been engaged in establishing the market demand for composted materials created from cow manure, with various combinations of nutrient additives. AGT worked closely with the Vermont Sustainable Jobs Fund (VSJF) to document the demand for bulk and bagged products, as well as willingness to pay for locally produced fertilizer for use by Vermont farmers, in home gardens, specialty crop growers, etc. A required Market Research report documenting the demand and market potential for these products was submitted by AGT in March of 2020.

AGT continues to work on equipment fabrication, site development tasks, and additional business planning. Equipment fabrication involved the ordering of components and the assembly of the AGT Compost Hot Box 250-8R at the company shop in Cambridge, VT. This equipment, the compost aeration and heat recovery (CAHR) unit, is mounted inside an insulated 20’ shipping container which produces compost from phosphorus (P) containing ingredients including livestock manure (separated dairy manure solids, scraped manure and pen manure), wood chips, leaves, sawdust, waste feed, and P concentrate (from a Digested Organics LLC ultrafiltration unit).

The unit is monitored and controlled remotely in order to reduce on-site labor demands and optimize operation. Fabrication of the permanent CAHR unit was completed and the unit was transferred to the Magnan Brothers Dairy LLC, Burnor Farm on May 6, 2021 and began operations. In total, 75 CY were sold off farm in 2021, roughly half the input or volume feedstock of 150 CY. This accounts for 20% of the 2021 finished product. 307 CY has been logged in inventory for preparation of spring 2022 sales; this accounts for 80% of the finished product. 5 CY of finished product (about 2% of total 20201 finished product) has been used in onsite demonstration gardens and in new blend testing.

345 CY are in current active production and 250+ CY have been stockpiled for pending batches. The most difficult aspects of the process are staging feedstocks, mixing materials in a homogenous fashion, and properly aligning the loaded windrows over the aeration pipes. The farm staff and site operation team have become more proficient at mixing and loading with each subsequent batch. To date, all material used off farm has been in smaller scale gardening and landscaping applications, and on farm uses have been for the demonstration gardens and prototyping compost mixtures. AGT is planning to work on the P-fortified compost using the P concentrate from Digested Organics’ UF unit (described above). The intent is for field trials and saleable products of and with this material to be available in 2022.

Burnor batch loading CAHR unit in background. (Agrilab Technologies, Inc. Photo)

Village of Essex Junction/University of Vermont

The University of Vermont and the Village of Essex Junction, along with several other partners have developed and been testing PePhlo (pronounced P Flow), a mobile, flexible, and scalable solution for Phosphorus capture and removal. PePhlo applications focus on reduced installation and operational costs without the investment needed for conventional Phosphorus removal “brick and mortar” approaches. Proprietary pipe descaling technology (PDT) is widely used throughout the United States in thousands of successful scale formation control applications. This technology may well prove to be immensely cost effective for Phosphorus removal in Vermont sized wastewater applications. The technology induces an oscillating electric field of variable amplitude and specific frequency that promotes formation and precipitation of crystalline minerals (i.e. Struvite) without dangerous and damaging adhesion normally associated with the formation of these compounds. PePhlo uses PDT coupled with an electric-filtration membrane filtration cell, to enhance Phosphorus capture and removal from the waste stream.

Struvite generation systems are employed to remove Phosphorus from waste streams originating from water resource recovery facilities. The new PePhlo System allows for controlled formation and removal of Struvite and Vivianite outside of the treatment process. The collected Struvite can be processed as a fertilizer resource outside of the wastewater facility. PePhlo is viable on a small-scale application because it uses an innovative application of pipeline descaling technology as a means of enhancing crystalline Struvite generation and Phosphorus removal. It also uses a proprietary electrical field on the filter that allows for efficient capture of the Struvite crystals generated. PePhlo enhanced Struvite generation and capture improves the scalability to Vermont-sized water resource recovery facilities and Vermont sized farms. Ongoing research was severely impacted with the shutdown of the UVM lab during the spring and early summer of 2020.

Construction of the PePhlo reactor designed during the capstone project was completed by the end of the initial VPIC Stage Three grant for this project. The immense success of the Pe-Phlo technology has resulted in a subsequent grant to finalize the Pe-Phlo technology and fabricate a portable unit capable of being transported to external wastewater treatment facilities. Research on the design and abilities of the electrified membrane filtration system has been ongoing and is a critical step in the next phase of this project and will continue into 2022. In addition to filtration, working on automation and branding has been a focus of the Project team. PePhlo is awaiting approval of several patents and confirmed intellectual property rights for the technology.

Sakib Khan was recently selected first in the New England Water Environment Association (NEWEA)’s innovation shark tank. (UVM Photo)

HISTORIC UPDATES

TIMELINE

Timeline and details for interested parties are as follows:

- On April 27, 2018, an invitation was issued for proposals to develop a “proof of concept” for processes or technologies that remove phosphorus from manure or other waste streams and make the recovered phosphorus available for beneficial reuse.

- By May 11, 2018, prospective applicants emailed their intent to participate in the challenge.

- On May 21, 2018, the Administration held a meeting from 1-3 pm at the Agency of Natural Resources (ANR) Annex with interested parties to field questions and discuss the challenge.

- Stage One proposals were received, via email, by 5pm EST on July 6, 2018.

- 12 teams that submitted responses to Stage One were selected to make an in-person presentation to the Evaluation Team on Septmeber 6, 2018.

- Six teams were selected to progress to Stage Two of VPIC, notification occured on September 30, 2018.

- Stage Two concluded on September 30, 2019.

- VPIC Finalists were notified on November 8, 2019.

VPIC RESOURCES

Click Here for Details on the VPIC: Phosphorous Innovation Challenge Brief

Click here for the VPIC FAQ Document: VPIC- Frequently Asked Question Document (updated June 27, 2018)

WATCH: Gov. Phil Scott’s Phosphorus Innovation Challenge Press Conference

CONTACT

Jeff Cook

Phone: (802) 828-3474

Email: Jeff.Cook@vermont.gov