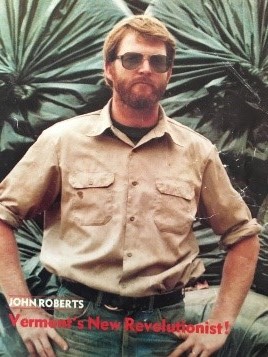

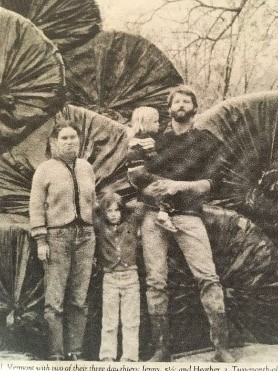

John Roberts and family featured on the cover of December 1982 Ag Review Magazine.

By Nina Gage, VT Agency of Agriculture, Food & Markets

In December of 1982 a monthly agricultural magazine based out of Putnam, CT called Ag Review included a story about a Vermont Dairyman who lived in Cornwall. This was Vermont’s own John Roberts, portrayed as “Vermont’s New Revolutionist!”.

John Roberts, an Englishman, first came to Vermont in 1972 to work at Shelburne Farms. He returned the following summer of 1973, eventually moved to Vermont permanently in 1974 and married the farmer’s daughter, Lisa Webb. John and Lisa started their own dairy farm in Cornwall, VT called Butterwick Farm. John had left a lot behind in England, but brought with him his subscription to English Farming Journals, in addition to his inclination to revolutionize of course.

There was an issue of Farmers Weekly from 1978, a long running magazine for the British farmer, where John read about a guy in England who put his bales in plastic bags. The article peaked John’s interest as Farmers from England and Vermont shared similar issues around making quality hay or silage with limited drying weather. Some research had occurred around stacking bales in silage bunkers, but feed quality was a consistent concern. The idea that you could bag individual bales of silage or hay with high moisture content was unheard of at the time, but quickly swept across England from 1981-1982.

Agricultural innovation in Vermont usually fits into one of two buckets; how to handle and store food for the winter months, or how to deal with Vermont’s completely unpredictable weather patterns. John’s individually wrapped round bales was meant to help a small farm tackle both.

This process enabled forage to be harvested sooner, in a twenty-four-hour good weather window, baled right away, and sent into fermentation. The feed when fed out months later, is preserved high-quality, high protein forage from the day when it was cut. The high moisture and a tight plastic seal made for a good fermentation environment.

While the practice of fermentation for extended food storage has been around for thousands of years, it has become a more recent obsession in the health foods world, from Kimchi to Kombucha. Little do people know, fermentation of animal feed has always been a major part of feeding livestock through the winter months. Our long and cold Vermont winters have clearly made for a fascination with fermentation (consider the boom in Vermont craft breweries). Wrapped round bales are just one example.

In the early 80’s, UVM Professor Sidney Bosworth was working for Penn State as a forage specialist. “I remember when I first met John….it was before the days of wrapping”. John had traveled to a farming conference to help sell other farmers on this English idea of individually wrapped bales, as well as to sell more Gehl balers, John’s baler of choice at the time. It was still the early days of making round bales rather than square. “When you’re the first one, the company gets you to sell it for them to other farmers,” explained Sid.

For John and Lisa, being the first to wrap round bales meant helping to pave the way for other farmers. With a new Gehl baler, plastic bags were the only other investment required for the Robert’s round bale silage system. This meant finding a plastic manufacturer willing to make the bags they needed. The first company told John he needed to order a minimum of 30,000 bags. After writing to a plastic company in England, who was already producing silage wrapping bags, John was able to have bags imported at a reasonable rate.

Challenges in those days also included working with chain style balers and making dense hay bales without causing mold. The manufacturers quickly caught on with belt balers which made a tighter bale. According to Sid, “as long as you’re using good principles of fermentation – it doesn’t matter where it is – bunk, bags or otherwise.” Wrapped round bales soon became a method of feed storage with big advantages for small farms. “It doesn’t require much labor and provided flexibility for putting up high quality forage,” Sid highlighted, and still, “it was a lot cheaper than buying a chopper.”

Living, learning, and earning in Vermont is about how to do things differently, in a small way but a good way, even for an Englishman.

Wrapped round bales can be a practical and economical feed storage option for small farms as it does not require construction of infrastructure such as silos or bunks. In the right location and with proper management, wrapped round bales can also reduce, and eliminate in some cases, the risk of leachate and runoff from feed storage areas to surface waters.”. There are still environmental impacts of wrapped bale feed management systems to figure out.

Agricultural plastics are a major waste stream coming off farms, and while certain types of plastics can be recycled, all plastics need to be properly disposed. Proper disposal as waste or recycling can depend on your solid waste district. For example, the Northwest Solid Waste District recycles bunker covers and plastic from ag bags. To find out which agricultural plastics you can recycle, and how to best prepare that plastic for recycling, get in touch with your local solid waste district at https://dec.vermont.gov/waste-management/solid/local-districts .

Editors Note: John Roberts currently works for the Agency of Agriculture, Food, and Markets as Agricultural Water Quality Specialist.