New Grants for Dairy Processors Across the Northeast

By Katie Spring, Northeast Dairy Business Innovation Center at VAAFM

In an ongoing effort to increase sustainability and resilience of the dairy supply chain across our 11-state region, the Northeast Dairy Business Innovation Center (NE-DBIC) announces two grants for dairy processors. Find the Request for Applications for the grants below, plus our full funding calendar, on our website: https://agriculture.vermont.gov/dbic/grants

Dairy Processor Research & Development Innovation Grant

New funding is available to support processing innovation across a variety of scales and to support dairy processors in gaining knowledge that will allow them to make informed, long- term business investments.

Centered on developing alternatives to current industry standards, project areas may include sourcing, novel product development, alternative production solutions, transportation and distribution, supply chain, operations, employee welfare, marketing, and consumer experience. An educational or information sharing component is required for all grants to benefit other regional dairy processors.

Grants will range from $75,000 to $250,000 with a 25% (cash or in-kind) match commitment required. Request for Applications will be available on January 10th. Application period is January 26 – March 23, 2023.

Existing Dairy Processor Expansion Grant

With a goal to diversify and strengthen the supply chain for dairy farmers and consumers, this grant offers existing dairy processors across the Northeast funding to acquire specialized equipment needed to increase the processing capacity of regionally produced milk and other activities to support expansion and meet demand.

Split into multiple funding tiers, this grant will accommodate processors of all scales. Larger awards will be required to participate in a multi-stage application process, while smaller award ranges will apply in a single round application process.

Requests for Applications will be released January 26th for the multi-stage process, while the single-stage application for smaller processors is estimated to open in spring.

For more information about these two grants, contact the NE-DBIC team at agr.dairyinnovation@vermont.gov

Sensory Directed Research on Artisanal Cheese to Benefit the Local, Regional, and National Dairy Industry

By Heather Darby and Roy Descroches, UVM Extension

“What’s a bug got to do with it?” might seem like a strange question, but it’s answer could increase the success of artisanal cheeses. In 2020, The Vermont Agency of Agriculture, Northeast Dairy Business Innovation Center (NE-DBIC) teamed up with the University of Vermont Extension to investigate factors that influence artisanal cheese flavor quality. Recently, Dr. Ben Wolfe (microbiology) and Dr. Scott Frost (chemistry) from Tufts University collaborated with UVM Extension to understand the complex connection between flavor, microbes, and chemistry, in artisanal cheese.

In August, the multi-discipline team travelled to collaborating cheese farms, Jasper Hill and Spring Brook, to collect a set of cheese samples to submit to a range of analytical tests. It was critical to have the various tests conducted on the exact same set of cheese wheels so that the data could be linked.

Preparing cheese samples for testing.

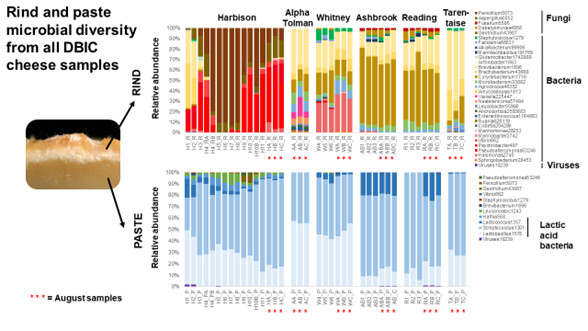

The sample set included multiple wheels of Alpha Tolman, Whitney, and Harbison from Jasper Hill, and Reading, Ashbrook and Tarentaise from Spring Brook. The UVM Extension trained panel tasted the samples, while Tufts University conducted microbiological and innovative chemical tests on the same samples. The various data sets are currently being analyzed and initial results are promising.

The microbial diversity results begin to tell an interesting story.

Microbial diversity of 4 different cheeses from Jasper Hill and Spring Brook.

What microbes are present?

Microbial diversity was influenced by the type of cheese and by the type of cellar the cheese was aged in. The microbial diversity results suggest the cheese samples fall into four clusters, with Harbison being unique, Alpha Tolman and Whitney similar, Reading and Ashbrook similar, and Tarentaise being slightly different.

How do they impact the taste of the cheese?

The sensory data suggests a similar story. When plotting flavor dimensions that typically represent cheese flavor (“Richness”) and quality (“Cleanness”), we see a similar picture to the microbial diversity result with Harbison (HAR) and Tarentaise (TAR) occupying unique positions on the flavor map, Alpha Tolman (ALT) and Whitney (WHT) plotting closer, as with Reading (REA) and Ashbrook (ASH).

Sensory data of the 4 cheeses evaluated in the study.

What type of chemistry do they create?

In addition to microbial and sensory data, we generated a robust chemical/sensory database on the cheese samples using a Gas Chromatograph/Mass Spectrometer (GC/MS) that was outfitted with an Odor Detection Port (ODP). The ODP allows a trained smeller to describe the odors as the GC/MS identifies chemical peaks. The chemistry data is currently being compiled. An example chromatogram for Harbison identifies a range of flavor compounds. The sensory information generated by the trained smeller at the ODP will be added to the chemistry results. Once completed, it will help us understand the contribution of chemical compounds identified in cheese to its flavor. In addition, it will help us begin to link flavor chemistry and microbial diversity to cheese flavor.

The gas chromatopraph/mass spectrometer and the trained smeller collecting cheese chemistry data

Chemical compounds identified from Harbison using the gas chromatopraph/mass spectrometer.

What’s a bug got to do with it?

Microbes generate the chemistry responsible for the cheese flavor we love. By understanding possible connections between microbes (bugs), chemistry, and flavor, we can help cheese makers engineer cheese in the future that optimizes customer satisfaction. Answering the question, “What’s a bug got to do with it?” is key to success.